The demand for sustainable design and manufacturing solutions is increasing worldwide and Australia is no different. With the nation turning towards minimizing its footprint on the environment and going green, one technology shines as the game changer in production: sustainable 3D printing. This technology that previously was confined to prototypes and novelty products is fast becoming an important tool for producing environmentally friendly products in most industries. From healthcare and construction to fashion and education, 3D printing is the future of Australia’s circular economy and net-zero emissions.

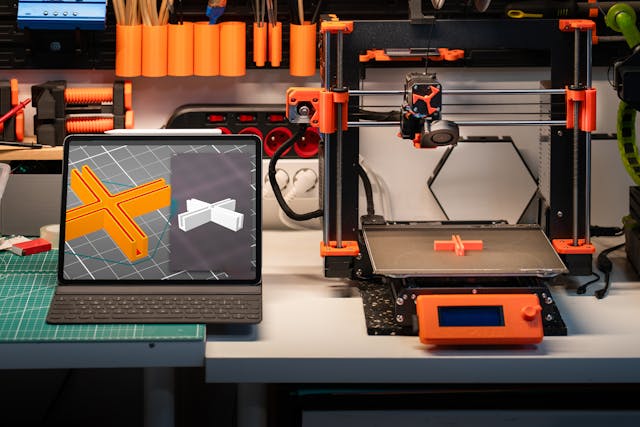

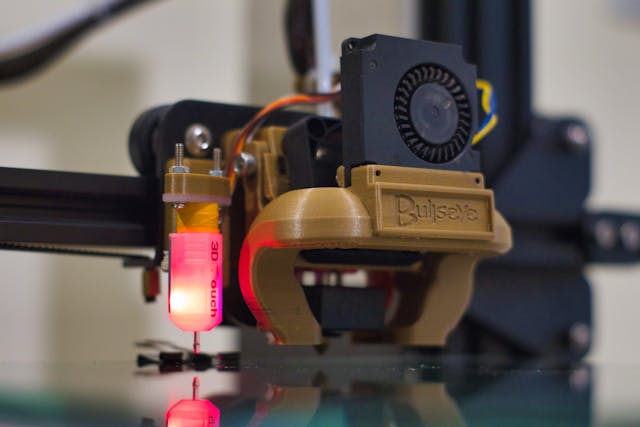

Rethinking Manufacturing with Additive Technology

Conventional manufacturing processes generate waste because of subtractive processes in which material is eliminated to create a product. 3D printing is a process of adding material layer by layer with just the amount of material needed. This minimizes waste and allows for new options in responsible resource utilization. Industries in Australia are beginning to use this technology not only for efficiency but also because it has such a low environmental impact. From recycling plastics to testing biodegradable filaments, manufacturers are reconsidering production lines with a focus on sustainability. Melbourne and Sydney companies are at the forefront, exploring custom 3D printing solutions for bespoke furniture, spare parts and even building elements that would otherwise be done using energy-intensive processes.

Material Innovation and Local Sourcing

Perhaps the most thrilling aspect of sustainable 3D printing is the material innovation. Australian start-ups and researchers are developing environmentally friendly filaments from organic waste, ocean trash and other local materials. For instance, Queensland projects are experimenting with seaweed-based materials, while others reuse agricultural residue such as sugarcane husks. This promotes the local economy and minimizes emissions from importing raw materials from foreign countries. Through using recyclable or biodegradable materials, 3D printing in Australia is also moving towards overall sustainability objectives and high performance and durability.

Lowering Carbon Footprint in the Built Environment

Construction is among the largest carbon emitters in the world and Australia is seeking cleaner alternatives. 3D printing is being seen as an answer in this regard. In Western Australia, building firms are piloting 3D printed building parts made from eco-friendly concrete mixes. These can be printed on site, lowering transport emissions and accelerating the build. In remote and regional communities this could be a game changer, cost effective and environmentally friendly housing solutions without the logistical nightmares of standard building practices. By embracing this style of building Australia can minimize waste, save money and construct more energy efficient buildings.

Applications in Healthcare and Education

Sustainability is a large part of what has brought 3D printing into play in health and education in Australia. In the hospitals which is the primary setting for this, the tech is being used for development of custom prosthetics, surgical equipment and anatomic models at a lower waste level. Also which in turn improves patient results and supports health care’s push towards better responsible use of resources. In the school and university settings we are seeing 3D printing put into the core of STEM curriculums as a way to present innovation and sustainability at the same time. We are reporting that schools are using recycled materials and are getting students to design practical, green solutions for real world issues. This in turn is to make the next set of Australian designers and engineers well prepared to take up the mantle of sustainable design.

Challenges and Opportunities for National Adoption

Although we understand the importance of sustainable 3D printing, we also identify that there are challenges which have to be overcome to achieve broad scale use within Australia. Affordability is a major concern which subsequently implicates small firms which might lack the resources needed to acquire required equipment and inputs. Also access to training and professional skills is variable which a problem in rural and remote communities is. But we are witnessing growth in this field. The government is issuing grants and universities are conducting research which is assisting in closing these gaps along with which we are witnessing public support for sustainable practices increase. As infrastructure becomes better and costs decrease more Australian sectors will enter to take advantage of 3D printing.

Sustainable 3D printing is a step beyond technological enhancement—it is a shift in what we value to responsible production, local resilience, and environmental stewardship. As Australia transitions through the climate change and economic transition stages we might witness in the uptake of this new technology a way to a green and sustainable future.